|

What is Lean?

A 'lean' process is one which

is focused on generating value for its customer. The flow of value through

the process is defined and tracked while waste in all its forms is removed.

|

Value

Value-added activity

An activity that transforms or

shapes material or information to meet

customer value requirement |

Waste

Non value-added activity

Those activities that take time or

resources, but do not add to customer value. There are seven

types of waste |

|

The Seven Types of Waste |

Type of

Waste |

Description |

|

|

Over Production |

Product made

for no specific customer |

|

Waiting |

Product waiting

to be processed |

|

Transport |

Moving the

product to several locations |

|

Inventory |

Storing product

costs money |

|

Over processing |

When a process

step does not add value |

|

Motion |

The excessive

movement of people |

|

Defects |

Errors during

the process |

Back to Top

What is Six Sigma?

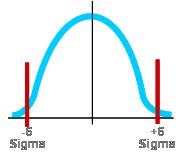

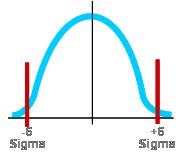

A six sigma process is one

which generates only three defects per million parts produced by the

process. It measures, reduces and tracks variation ensuring the processes

operate as intended. Its principles can be used both within manufacturing

and service environments.

|

Defects

DPMO

Three defects per million

opportunities (DPMO) is equivalent to 99.9997% of product

being within specification |

|

Variation

Standard deviation

A DPMO of three is equivalent to six sigma

|

Back to Top

How Lean and Six Sigma Fit Together

(LSS)

Of the many ways that lean six

sigma could be explained, the following three definitions are typical:

|

Lean and Six Sigma (1) |

Lean and Six Sigma (2) |

A Lean Six Sigma Process |

|

|

|

|

Back to Top

Why LSS?

Back to Top

Copyright ©

MIME Solutions Ltd. 2007 all rights reserved |